Revealed: The Intelligent Guardian of Industrial Cleaning – QK-TOP-2403A01 Monitor

In industrial production, the cleaning quality of closed containers directly affects product safety and overall quality. Residual contaminants, if overlooked, can pose serious risks to the production line, acting as potential "time bombs." When a cleaner is used to clean the interior of a tank, can it truly guarantee complete safety? Today, we will explore an advanced industrial cleaning technology—the QK-TOP-2403A01 monitor—and examine how it serves as the intelligent guardian of the cleaning process.

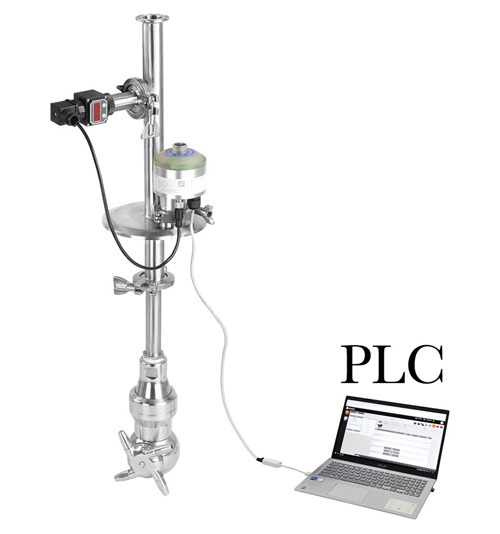

The QK-TOP-2403A01 monitor is specifically designed to evaluate the effectiveness of cleaners within enclosed tanks. Traditionally, determining whether a tank was thoroughly cleaned relied heavily on manual inspection and random sampling, which not only lacked efficiency but also increased the risk of missed detections. With the introduction of this monitor, such limitations have been overcome. If the cleaning process does not meet the required standards, the device immediately sends a feedback signal to the PLC system and uses LED indicators of different colors to visually display the operational status of the cleaner, making the cleaning outcome clearly identifiable in real time.

Its capabilities extend far beyond basic monitoring. The automatic teaching function of the QK-TOP-2403A01 acts like a tireless instructor, capable of quickly learning and adapting based on the unique characteristics of various cleaning machines and container types. This enables precise parameter settings, significantly reducing the time and effort required for manual calibration and enhancing overall cleaning efficiency.

Pressure fluctuations in industrial environments can greatly affect cleaning performance. The pressure level setting and anomaly detection features of the QK-TOP-2403A01 serve as a reliable "safety guard." Users can customize pressure thresholds according to specific requirements. In the event of abnormal pressure conditions, the monitor issues immediate alerts through color-coded LED lights and simultaneously transmits output signals, enabling prompt corrective actions and preventing incomplete cleaning or equipment damage.

The monitor’s ineffective cleaning detection function functions as its “sharp eyes,” capable of identifying even the smallest cleaning imperfections. No residue hidden in the corners of the tank can escape its detection. Upon detecting any deviation from effective cleaning, the device activates corresponding LED indicators and sends a signal to the PLC system, ensuring that cleaning flaws are promptly addressed.

Additionally, the mechanical fault detection capability of the QK-TOP-2403A01 operates like a vigilant “device doctor.” It continuously monitors the mechanical condition of the cleaning equipment during operation. Should potential issues such as bearing wear or component loosening arise, the monitor provides timely warnings via changes in light color and signal feedback, allowing staff to identify and resolve problems before they escalate. This proactive approach minimizes equipment downtime and ensures uninterrupted production.

With these comprehensive functionalities, the QK-TOP-2403A01 monitor has demonstrated significant value across industries such as food processing, pharmaceuticals, and chemicals. For example, after implementing this monitor, a food manufacturing company reported a 70% reduction in defective products caused by inadequate cleaning. Similarly, a pharmaceutical enterprise successfully identified and resolved a mechanical fault early, avoiding substantial equipment losses amounting to hundreds of thousands of yuan.

If you are facing challenges related to inconsistent cleaning quality or difficulty in diagnosing equipment failures, the QK-TOP-2403A01 monitor may offer the solution you need. By integrating intelligent monitoring into the cleaning process, it establishes a robust safeguard for both production safety and quality enhancement.