Arc-shaped rotary valve – introducing an innovative solution for industrial fluid control

The distinctive structural design of the arc-shaped rotary valve

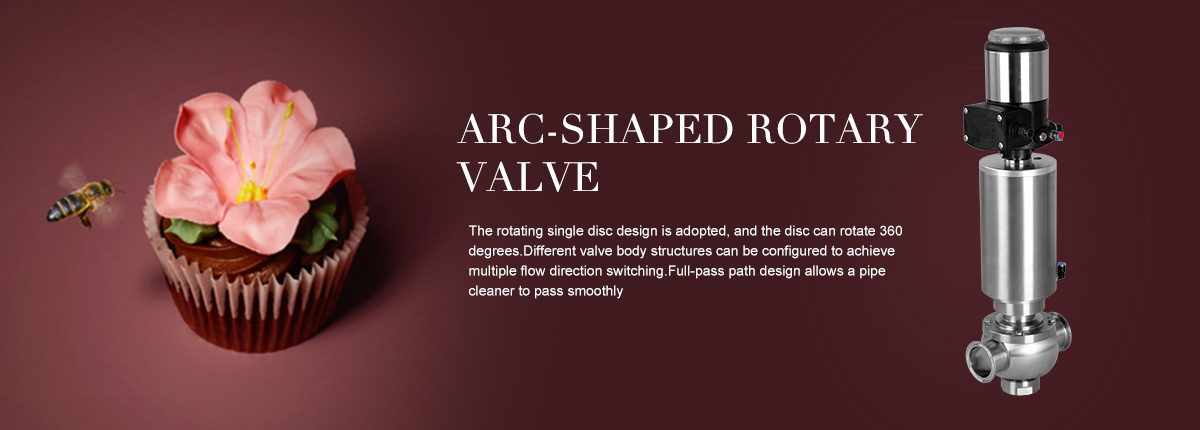

The most notable feature of the arc-shaped rotary valve is its rotary single-disc mechanism, which allows the disc to rotate 360 degrees in all directions. This unique design significantly enhances its ability to control fluid flow. When fluid needs to pass through the valve, the single disc rotates smoothly, opening the flow channel with minimal resistance and reducing energy loss. In contrast, when the flow needs to be interrupted, the disc can rapidly rotate and tightly conform to the valve seat, ensuring a secure seal and eliminating the risk of leakage. This 360-degree rotational mechanism ensures a more efficient and seamless opening and closing process, thereby improving the valve's response speed and control precision. As a result, fluid regulation in industrial applications becomes more accurate and dependable.

Furthermore, the arc-shaped valve is equipped with a cleaning function that utilizes a rubber pig head (PIG). When the pig head is introduced into the pipeline, it removes debris adhering to the pipe walls through friction, while the annular gap jet simultaneously flushes away accumulated contaminants.

Versatile valve body configurations and flow direction adaptability

The arc-shaped rotary valve can be configured with various valve body structures to support multiple flow direction adjustments, meeting the diverse and dynamic demands of industrial processes. For example, in production environments requiring frequent changes in fluid direction, the valve can be adapted to enable forward and reverse flow, as well as switching between different branch pipelines. This flexibility allows for precise guidance of fluid movement within the pipeline network, ensuring orderly and efficient flow. This feature provides a reliable foundation for the continuous and stable operation of industrial systems.

Advantages of the full-bore design

Another key feature of the arc-shaped rotary valve is its full-bore design, which allows pigging devices to pass through the valve unimpeded. This design not only improves the efficiency of pigging operations but also minimizes wear and energy consumption during the passage of the pigging device. Additionally, the full-bore configuration ensures consistent flow velocity and pressure across the valve, reducing pressure drop and turbulence, and enhancing the overall conveying efficiency and stability of the pipeline system. In industrial applications with stringent flow and pressure requirements—such as long-distance natural gas pipelines and material transport systems in large chemical plants—the full-bore design of the arc-shaped rotary valve demonstrates significant advantages, contributing to the efficient and stable operation of the entire system.

Technical specifications

Size range: 1.5"–4" / DN40–DN100

Pressure range: Full vacuum to 10 bar

Operating temperature: -10°C to 120°C (optional up to 150°C)

Suitable media: Water, oil, gas, and other compatible fluids

Connection types: Clamp, welded, threaded, flanged

Air supply pressure: 5–7 bar

Air supply connection: G 1/8

Valve body types: Straight-through, three-way T-type, three-way Y-type

Material of metallic components: AISI 304 / 1.4301, AISI 316L / 1.4404

Sealing material: PTFE (with EPDM as auxiliary seal)

External surface finish: Matte, sandblasted

Internal surface finish: Bright (polished), Ra < 0.8 μm