In-Depth Analysis: Efficient Operation, Flow Control, and Functional Advantages of Pneumatic Angle Seat Valves

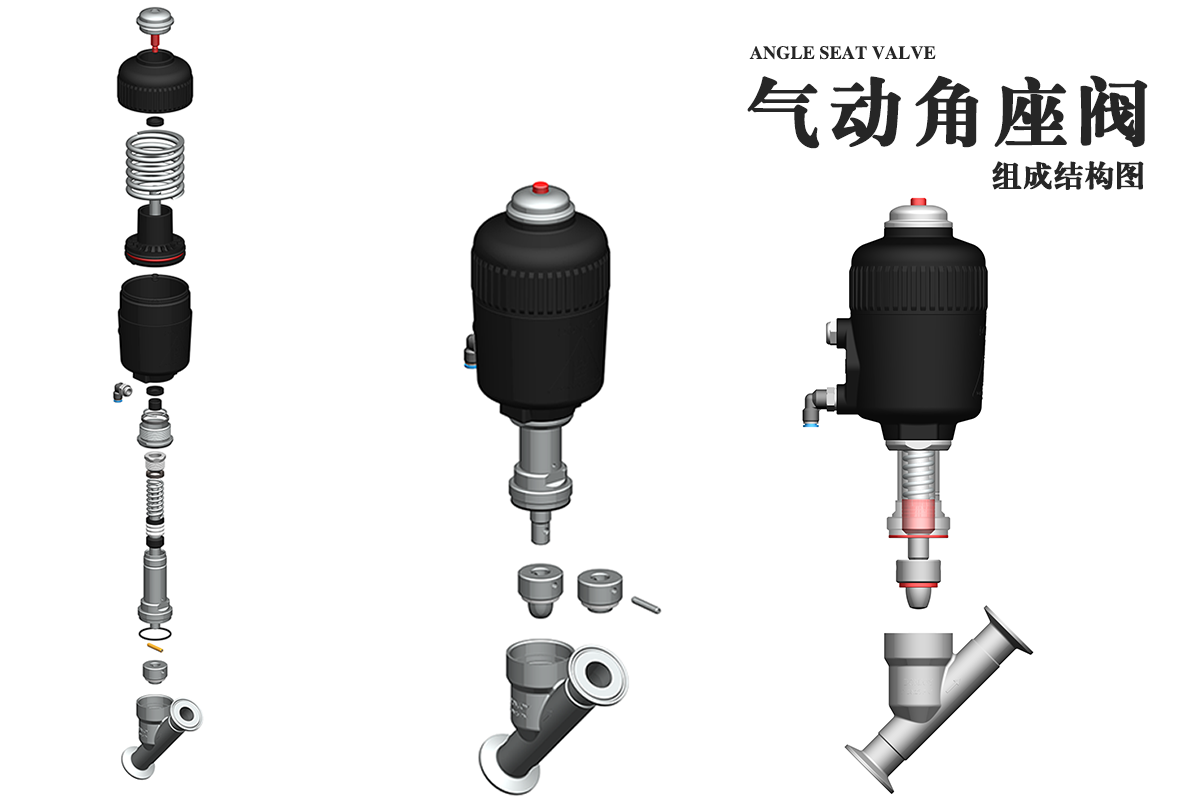

The latest pneumatic angle seat valve developed and manufactured by DONJOY Technology Co., Ltd. features a distinctive angular design that enhances space efficiency during installation and enables seamless integration into complex pipeline systems. The valve consists of key components including the valve body, pneumatic actuator, valve core, and valve stem. The valve body is typically constructed from materials such as stainless steel or plastic and incorporates an angular flow channel that allows fluid to change direction by 90° within the pipeline, significantly reducing flow resistance. Based on operational mode, these valves are classified as either single-acting or double-acting types.

Distinctive Design and Performance Advantages

1. Compact Structure and Space Efficiency

The innovative angular seat configuration minimizes spatial requirements during installation, making it ideal for industrial applications with limited space. Its compact dimensions allow for flexible placement in confined areas without compromising system integrity, thereby enabling a more streamlined and efficient pipeline layout. This design contributes to optimized spatial utilization and supports cost-effective plant design.

2. Low Flow Resistance, High Efficiency, and Energy Savings

The internal flow path has been precisely engineered to maintain stable fluid velocity, minimizing turbulence, impact, and wear on internal components. As a result, flow resistance is substantially reduced, allowing fluids to pass through with minimal pressure loss. In industrial processes, this translates into lower energy consumption for fluid transport, improved operational efficiency, and reduced operating costs.

3. Quiet Operation Without Noise Generation

During opening and closing cycles, the valve employs a specialized damping mechanism and high-performance sealing materials to eliminate mechanical impacts and friction between moving parts. This ensures silent operation, a critical advantage in environments where noise control is essential for workplace safety and comfort.

4. Dead-End-Free Design Ensures Hygienic Cleanability

The internal geometry is carefully designed to eliminate dead zones or stagnant areas where contaminants could accumulate. In hygiene-sensitive industries such as food and pharmaceuticals, this feature facilitates thorough and efficient cleaning. The absence of residual material inside the valve ensures product purity, prevents cross-contamination, and supports compliance with stringent sanitary standards, thereby safeguarding product quality and consumer safety.

5. Zero Leakage for Enhanced Safety and Reliability

Equipped with advanced sealing technologies and premium-grade sealing materials, the pneumatic angle seat valve achieves reliable zero leakage performance under normal operating conditions. This characteristic is vital in high-risk sectors such as chemical processing and gas handling, where even minor leaks can compromise safety and process integrity.

Innovative Features for Enhanced Flexibility

6. Interchangeable Valve Disc for Versatile Applications

The valve supports easy replacement of the valve disc, allowing users to switch between standard on/off and modulating control configurations based on specific process requirements. The replacement process is straightforward and does not require specialized tools or technicians. With minimal training, operators can perform disc changes efficiently, enhancing maintenance flexibility and operational adaptability.

Technical Specifications

- Size Range: 0.5"–4" / DN10–DN100

- Pressure Range: Full vacuum up to 10 bar

- Operating Temperature: –10°C to 150°C (optional up to 180°C)

- Applicable Media: Water, oil, gas, steam, and other compatible fluids

- Connection Types: Clamp, welded, threaded, flanged

- Air Supply Pressure: 5–7 bar

- Air Port Connection: G 1/4

- Materials: AISI 304 / 1.4301, 316L / 1.4404

- External Surface Finish: Matte, sandblasted

- Internal Surface Finish: Bright polished, Ra < 0.8 μm

- Seat Seal Material: PTFE

Broad Application Scope Demonstrates Proven Value

In the food and beverage industry, where hygiene is paramount, pneumatic angle seat valves play a critical role throughout production processes—from raw milk collection and transportation to processing and final packaging. These valves enable precise control over the flow of milk, additives, and cleaning agents, ensuring process stability, preventing cross-contamination, and guaranteeing consistent product quality. In beer brewing, they regulate wort transfer, fermentation, filtration, and filling operations. Integrated into CIP (Clean-in-Place) systems, they facilitate rapid switching of cleaning solutions, maintaining equipment hygiene and supporting the production of high-quality beverages.

In the pharmaceutical sector, where product safety directly impacts human health, strict process control is mandatory. Pneumatic angle seat valves are employed in drug synthesis, purification, and formulation stages to accurately manage the flow of raw materials, solvents, and gases. For example, in an aseptic manufacturing facility, these valves control steam supply to moist heat sterilizers, enabling precise temperature regulation and ensuring compliance with rigorous sterilization protocols. In biomedical applications, such as infusion pumps and in vitro diagnostic devices, they enable accurate metering and transport of minute liquid volumes, contributing to advancements in medical technology.

The chemical industry involves complex processes with highly corrosive, flammable, and reactive media, demanding robust and reliable valve performance. In large-scale chemical plants, pneumatic angle seat valves are used to control the transfer of acids, alkalis, organic solvents, and other aggressive substances. Constructed from corrosion-resistant alloys and equipped with perfluoroelastomer seals, these valves withstand harsh chemical environments, prevent leakage, and ensure safe operations. During chemical reactions, they provide accurate feed and discharge control, optimizing reaction conditions, improving yield, and enhancing overall process efficiency—delivering significant economic benefits.

Water treatment represents another major application area. In municipal wastewater treatment facilities, numerous pneumatic angle seat valves are deployed to regulate influent and effluent flows, distribute streams, and dose treatment chemicals. Their precise control capabilities support stable system performance and ensure compliant discharge standards. In industrial wastewater treatment, they enable accurate dosing of reagents tailored to specific waste streams—such as those containing heavy metals or organic pollutants—facilitating effective remediation. Additionally, in water reuse and rainwater harvesting systems, these valves contribute to sustainable water resource management by enabling reliable fluid control across recycling loops.

With their unique structural design, superior performance characteristics, and innovative functionalities, pneumatic angle seat valves have established themselves as a trusted solution across diverse industrial domains. From compactness and low resistance to silent operation, hygienic design, leak-tight sealing, and modular replaceability, each feature delivers tangible benefits that enhance productivity, safety, and sustainability. As a result, they are widely adopted in industries including food and beverage, pharmaceuticals, chemicals, and environmental engineering, demonstrating strong technical capability and extensive application potential.