Introducing the QK-TOP-2403A01 Monitoring System: An Intelligent Solution for In-Process Verification of Container Cleaning Efficacy

In industrial manufacturing, the cleanliness of enclosed process containers is a critical determinant of product quality, regulatory compliance, and operational safety. Inadequate cleaning may result in residual contaminants—such as particulates, microorganisms, or chemical residues—that pose latent risks to downstream processes and final product integrity. While “100% cleaning assurance” remains an aspirational benchmark, objective, real-time verification is essential to support robust process validation and risk mitigation. This document presents the QK-TOP-2403A01 Monitoring System—a purpose-built, non-invasive solution for continuous, quantitative assessment of internal container cleaning performance.

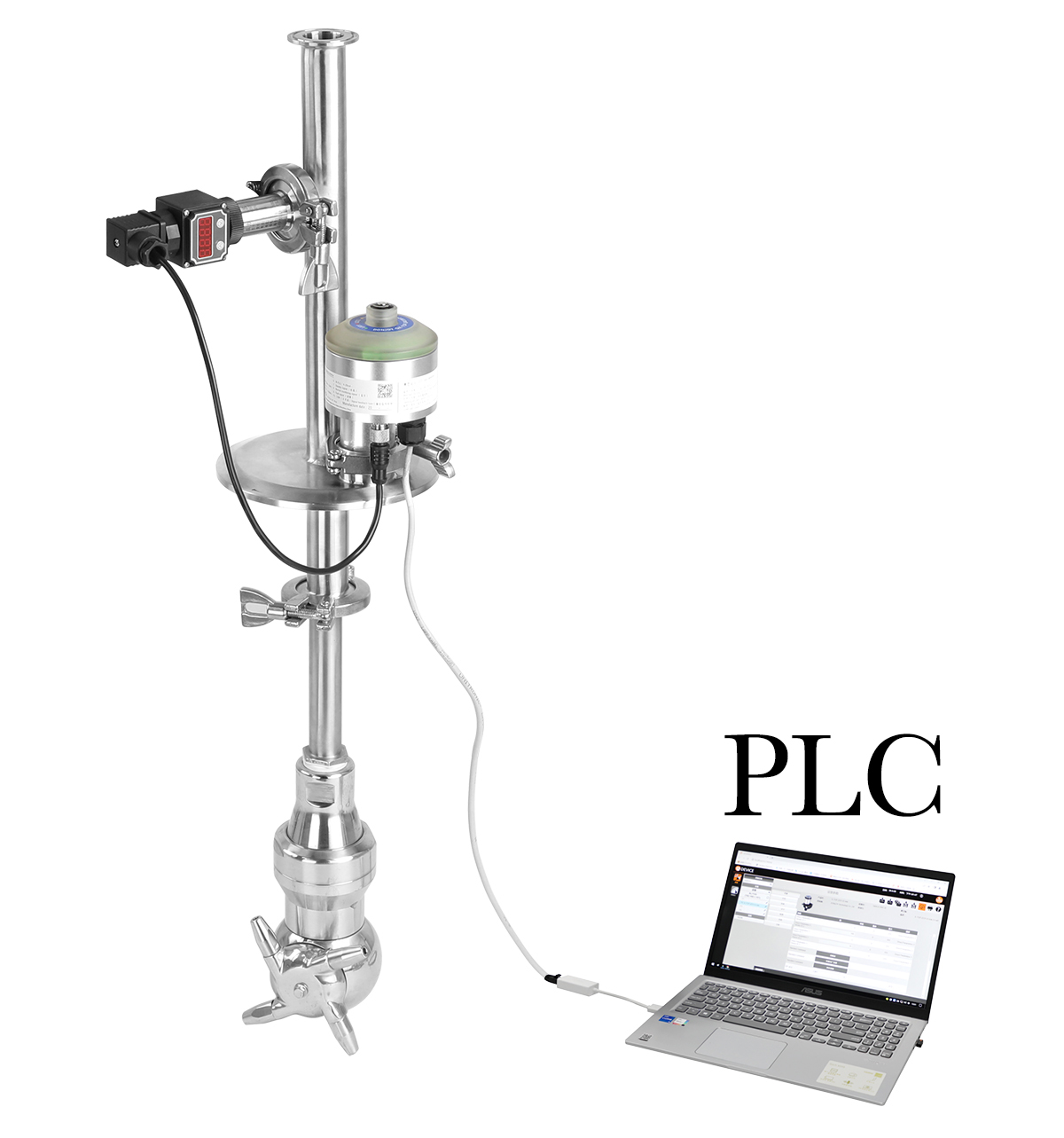

The QK-TOP-2403A01 system addresses longstanding limitations in conventional cleaning verification methods, which have historically relied on subjective visual inspection, operator experience, or infrequent sampling—approaches prone to inconsistency, sampling bias, and undetected failures. By contrast, the QK-TOP-2403A01 integrates seamlessly with programmable logic controller (PLC) infrastructure to provide automated, real-time feedback. Upon detection of suboptimal cleaning conditions—such as insufficient rinse coverage, inadequate dwell time, or persistent residue—the system triggers an immediate alert signal to the PLC and conveys process status via a multi-color LED interface. Each color corresponds to a defined operational state (e.g., “cleaning in progress,” “verification passed,” “anomaly detected”), enabling rapid, unambiguous interpretation by operators and supervisors alike.

Beyond real-time monitoring, the system features an automated calibration and teaching function—designed to adapt to diverse container geometries, material reflectivities, and cleaning protocols without manual intervention—thereby enhancing both deployment flexibility and long-term measurement reliability.