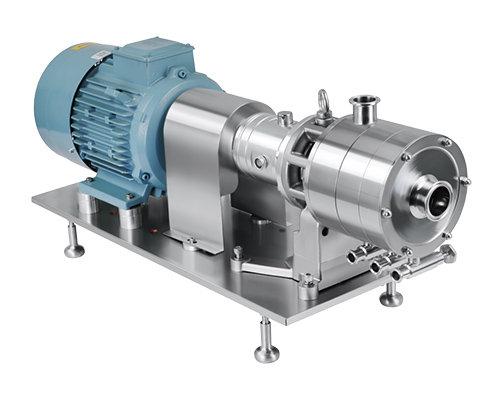

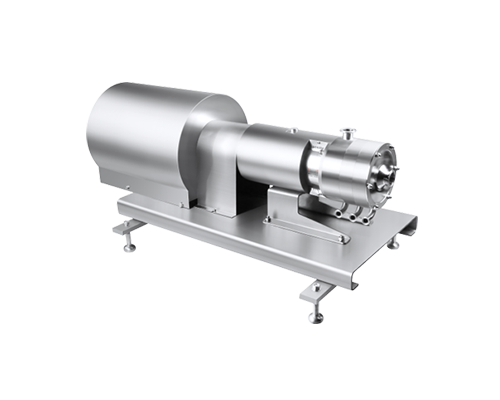

Application

The JZ3 series is an in-line continuous production emulsified homogenizing pump consisting of stator and rotor. The treated material will be dispersed, sheared, refined, crushed and emulsified step by step through total 12 layers of rotor and stator. Mixing, homogenizing, etc. Compared with the traditional production process, the pump is simpler, more convenient and optimized, it improve the production efficiency and quality of the material to be treated. Mainly used in various industrial fields such as food, beverage, pharmaceutical, health care, fine chemicals, coatings, pesticides, daily washing, photo paper, etc.

Technical specifications

Maximum flow rate Max Flow rate: 50m3/h

Maximum power Max power :55KW

Maximum temperature Max temperature: -20 ° C to 140 ° C

Material refinement Media refinement: ≤ 100 GRIT (≈ 200μm) ≤100 mesh (approx. 200μm) Material: 304 /316L, 1.431/1.4404, ASME BPE 316L, 1.4435 NB2 Fe≤0.5%

Surface treatment: ≤ Ra0.8μm, ≤ Ra0.6μm, ≤ Ra0.4μm

Machine seal: single seal and double seal

Inlet/Outlet Connection: Thread, Clamp, Flange, Aseptic Flange

Certification: 3-A-02-10 (N.O.1579); MD/06/42-EC (N.O.70521616101-00); FDA 177.2600; USP CLASS-II; EG/VO1935/2004;