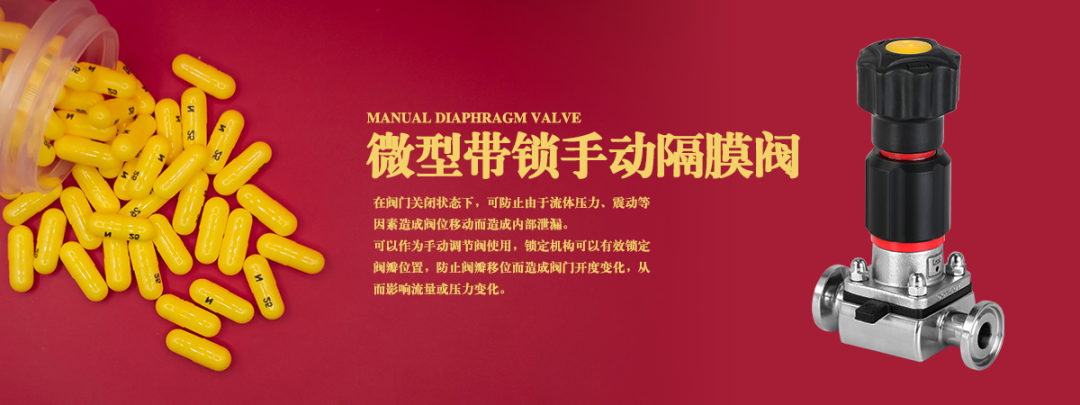

The Mini type lockable manual diaphragm valve offers precise flow control and enhanced safety through an integrated locking mechanism. Despite its compact size, it delivers exceptional functionality and reliability, making it suitable for a wide range of industrial, scientific, and medical applications.

This valve operates manually to regulate fluid on-off and flow rate, featuring a robust locking function at the stem. By adjusting the handwheel to position the disc accurately, the locking mechanism secures the valve in place, preventing unintended displacement caused by pressure fluctuations, system vibrations, or accidental impacts. This ensures stable flow conditions, improves operational safety, and enhances control accuracy.

Key product features include:

- Locking Function: The integrated mechanical lock fixes the valve stem position after adjustment, effectively eliminating risks of internal leakage due to external disturbances and ensuring process integrity.

- Miniaturized Design: With a compact structure, small footprint, and lightweight construction, the valve is ideal for space-constrained environments such as laboratory instruments, analytical devices, and microfluidic systems.

- Superior Sealing Performance: Utilizing a surface-contact seal between the diaphragm and seat, the design eliminates the need for packing or O-rings, reducing particle entrapment risks. The diaphragm fully isolates the actuation components from the medium, preventing cross-contamination and ensuring excellent leak-tightness.

- Corrosion Resistance: Constructed with corrosion-resistant materials such as 316L stainless steel and fluoropolymer linings (e.g., PFA), the valve withstands exposure to aggressive chemicals including strong acids, alkalis, and organic solvents, making it suitable for demanding chemical processing environments.

- Ease of Operation and Maintenance: Equipped with precision screw-driven actuation, the valve enables smooth and accurate modulation of flow. Its simple assembly facilitates easy disassembly, cleaning, and maintenance.

Technical Specifications:

- Size Range: 0.25"–0.75" / DN6–DN15

- Pressure Rating: Full vacuum up to 10 bar

- Temperature Range: –10°C to 120°C (optional up to 150°C)

- Media Compatibility: Water, oil, gas, and various chemical fluids

- Connection Types: Clamp, welded

- Body Materials: AISI 304 (1.4301), 316L (1.4404)

- Surface Finishes:

- External: Matte or sandblasted

- Internal: Electropolished, Ra < 0.8 μm

- Diaphragm Seal Options: EPDM, FPM, EPDM+PTFE

Application Areas:

- Laboratory Analysis: Used in liquid chromatography and mass spectrometry for precise metering of trace reagents. Flow channels can be as narrow as 0.1 mm, with repeatability accuracy reaching ±0.5%.

- Biomedical Engineering: Employed in drug delivery and dialysis systems using medical-grade silicone diaphragms compatible with gamma irradiation sterilization, ensuring biocompatibility and accurate dosing control.

- Food and Beverage Industry: Designed with minimal dead zones, facilitating efficient cleaning and disinfection. Meets stringent hygiene standards for use in beverage production and food processing lines.

- Semiconductor Manufacturing: Controls the flow of high-purity chemicals in wet etching processes. Constructed with ultra-clean materials such as PFA and perfluoroether rubber, with metal ion leaching below 1 ppb, meeting strict electronic industry cleanliness requirements.

- Industrial Processes: Applied in chemical processing, electroplating, photovoltaics, and waste treatment systems for handling media containing suspended particles or solids, such as landfill leachate and plating solutions.

.jpg)

The locking mechanism of the mini manual diaphragm valve provides significant practical advantages beyond basic flow control. It plays a critical role in enhancing both operational safety and product quality.

Ensuring Operational Safety: When closed, the locked valve stem acts as a physical barrier that prevents any movement under pipeline pressure or mechanical vibration. This eliminates the risk of leakage due to unintended valve opening, thereby safeguarding personnel, equipment, and the environment.

Improving Product Quality: In industries where consistency is paramount—such as pharmaceuticals and food production—the ability to set and lock the valve at a precise opening ensures uninterrupted process conditions. For example, in pharmaceutical manufacturing, this feature has been shown to increase production yield from 85% to over 95%, significantly improving batch-to-batch uniformity and compliance with quality standards.