Pneumatic Globe valves: An efficient solution for industrial fluid control systems

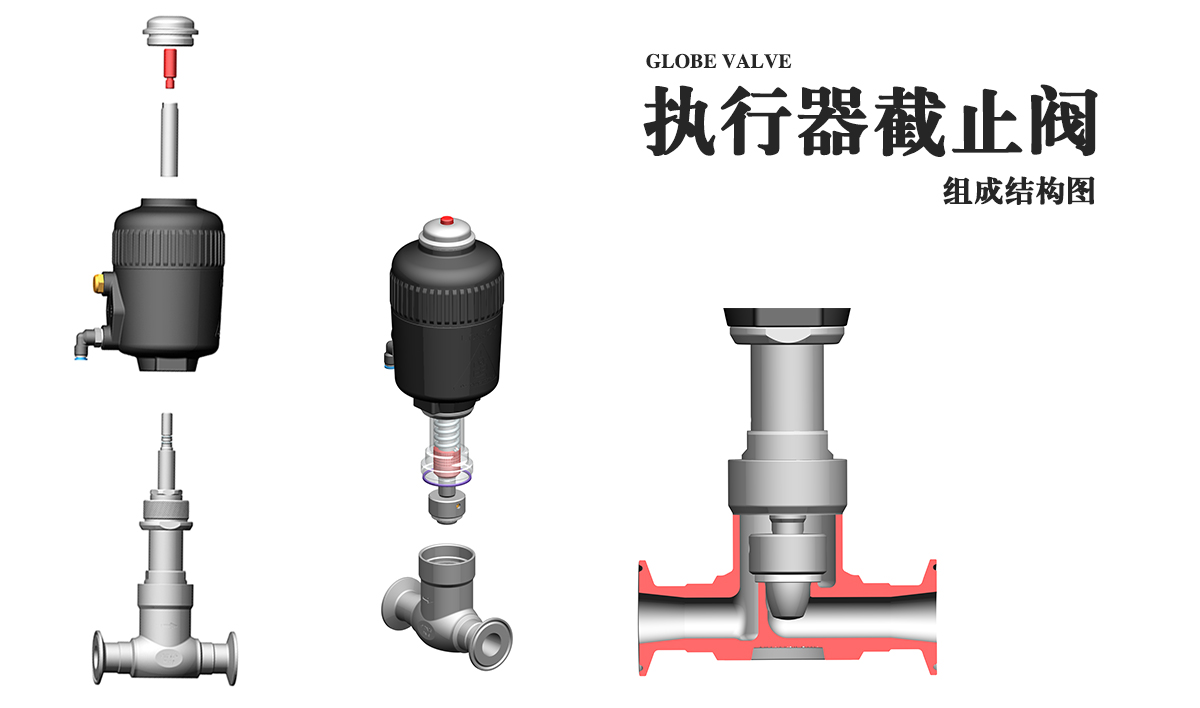

The latest generation of pneumatic globe valves is a type of valve actuated by compressed air, designed to reliably isolate or permit the flow of media within industrial pipelines, thereby ensuring the stable and orderly operation of industrial processes. The operational principle relies on the pneumatic actuator: upon receiving an external control signal, the actuator converts air pressure into mechanical force, which adjusts the valve's opening position to regulate fluid flow. When the actuator receives a signal to supply compressed air, the pneumatic piston drives the valve stem downward, separating the valve disc from the valve seat and thus opening the valve to allow smooth media passage. Conversely, when the control air is cut off, the piston retracts the valve stem, pressing the valve disc firmly against the valve seat to achieve a complete seal and prevent any media leakage.

Performance advantages

1. Compact structure and low flow resistance: Pneumatic stop valves feature a highly compact design with minimal footprint, making them ideal for industrial facilities where space is limited. Their installation helps conserve valuable floor space and facilitates more flexible equipment layout. Additionally, their low flow resistance ensures efficient media transmission through pipelines, reduces energy consumption, and enhances overall production efficiency—similar to how unobstructed lanes on a highway enable faster and smoother traffic flow.

2. Superior sealing and quiet operation: These valves operate silently during opening and closing cycles, with no dead zones and zero leakage performance. This makes them particularly suitable for applications requiring high hygiene and environmental standards. In the food and beverage industry, where contamination risks must be minimized, the zero-leakage characteristic prevents product spoilage and ensures food safety. In pharmaceutical manufacturing, the absence of internal cavities or blind spots eliminates the risk of residual substances, thereby maintaining drug purity and efficacy.

3. Installation flexibility: The valve can be installed in multiple orientations, allowing the same actuator to support both normally open and normally closed configurations. This design significantly enhances application versatility and reduces the need for multiple actuator types, lowering procurement costs and simplifying maintenance procedures.

4. Interchangeable valve disc design: Both standard on/off and regulating valve discs are available and can be easily replaced according to process requirements. When precise flow regulation becomes necessary due to changes in production conditions, users can simply replace the valve disc without changing the entire valve assembly. This modular approach saves time and cost while improving equipment utilization and adaptability.

Application fields

In the pharmaceutical industry, stringent hygiene standards demand equipment that prevents contamination at all stages of production. Even minor leaks or residue accumulation can compromise drug quality and patient safety. Pneumatic stop valves meet these demands through the use of corrosion-resistant materials and advanced surface finishing techniques, effectively preventing media leakage and cross-contamination. During liquid filling operations, these valves enable precise control over flow rate and velocity, ensuring consistent fill volumes and enhancing both production accuracy and product quality. The zero-leakage capability further minimizes waste and environmental impact, aligning with the pharmaceutical sector’s strict hygiene and sustainability requirements.

In the food and beverage industry, pneumatic globe valves provide accurate control over the flow of ingredients such as juice, water, and sugar solutions, ensuring consistent taste and product quality. In beer brewing, they regulate the addition of wort, hops, and yeast, as well as manage carbon dioxide release during fermentation, contributing to flavor stability and batch consistency. The valve’s cleanable design, free of stagnant zones, prevents bacterial growth and residue buildup, meeting rigorous food safety regulations and enabling consumers to enjoy safe, high-quality products.

As a critical component in modern industrial fluid control systems, pneumatic stop valves are expected to play an increasingly important role in future industrial development. With continuous technological innovation and proven performance, they contribute significantly to the advancement and modernization of industrial automation and process efficiency.