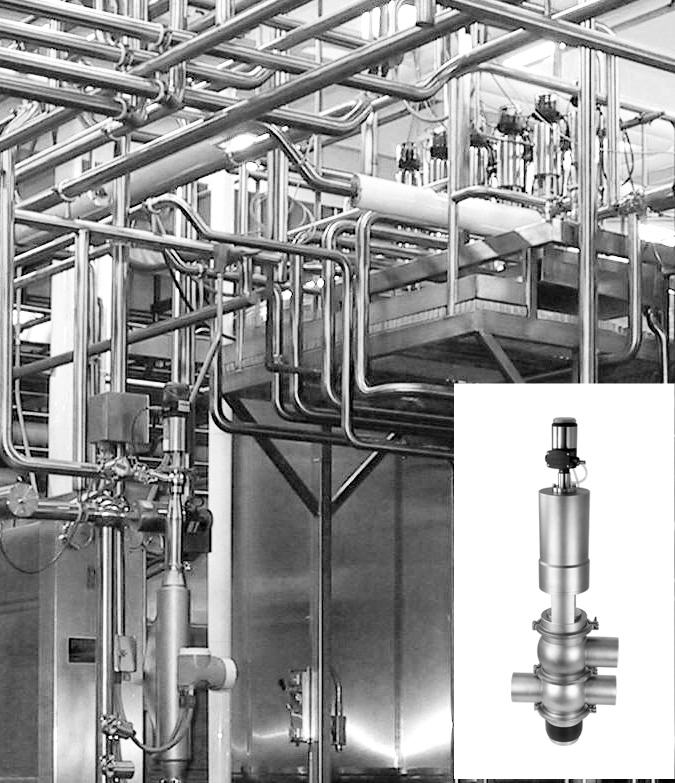

In the field of modern industry, fluid control is a vital task. However, problem that different fluids mixed has always plagued many companies. To solve this problem, Donjoy Technology Co., Ltd. has developed an excellent big mixing proof valve, which will become a powerful assistant for industrial safety and production efficiency.

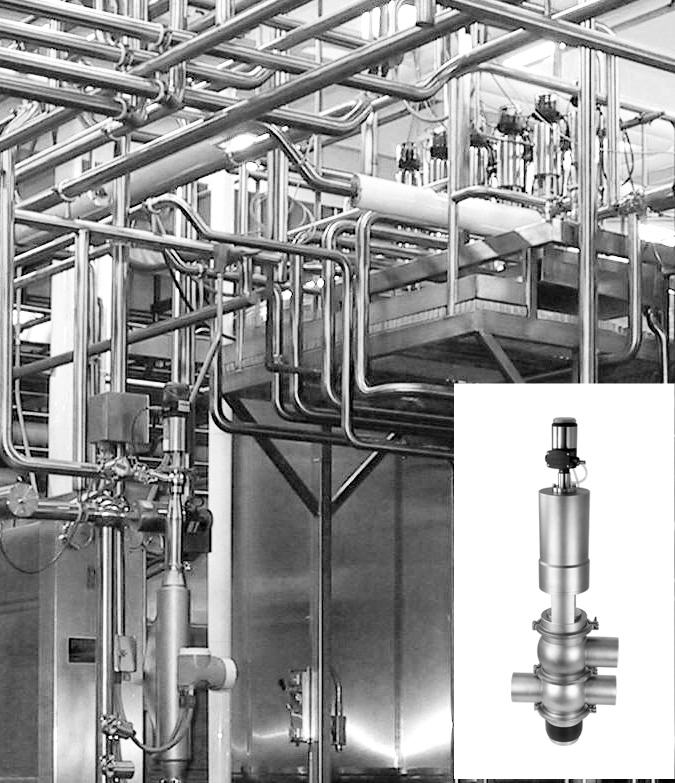

First, let's have insight into the technical characteristics of big mixing proof valve. The most significant advantage is that it can be cleaned and sterilized by the online original CIP. This technical characteristics can completely clean and disinfect the valve without disassembly. This not only greatly reduces the risk of maintenance costs and production interruptions, but also ensures the hygiene and safety of the production environment, and effectively prevents bacterial breeding and cross -pollution.

In addition, big mixing proof valve also have the technical characteristics of self -evaporation, no dead ends and non-retention. When the valve is closed, it can automatically empty the internal residual fluids to avoid the occurrence of dead ends and retention phenomena. This not only effectively prevents fluid mixing, but also ensures the cleaning and fluency of the pipeline system, which further improves production efficiency and product quality.

Of course, in addition to excellent technical characteristics, large -scale anti -hybrid valves also have very flexible configuration options. It can be combined with location feeders, valve control units, position sensors and other self -control systems to achieve precise valve control and monitoring. This flexible configuration enables the anti -hybrid valve to personalize according to different production needs and scenes to better meet the actual needs of the enterprise.

In practical applications, the anti -hybrid valve has been recognized and praised by users. Whether in food, medicine, chemical industry or other industries, it can exert excellent performance and bring significant benefits to enterprises. Many companies have said that the problem of fluid hybrid in the production process of large -scale anti -mixtures will be effectively solved, and production efficiency and quality will be significantly improved.